Final Steps to Ship Finished Products

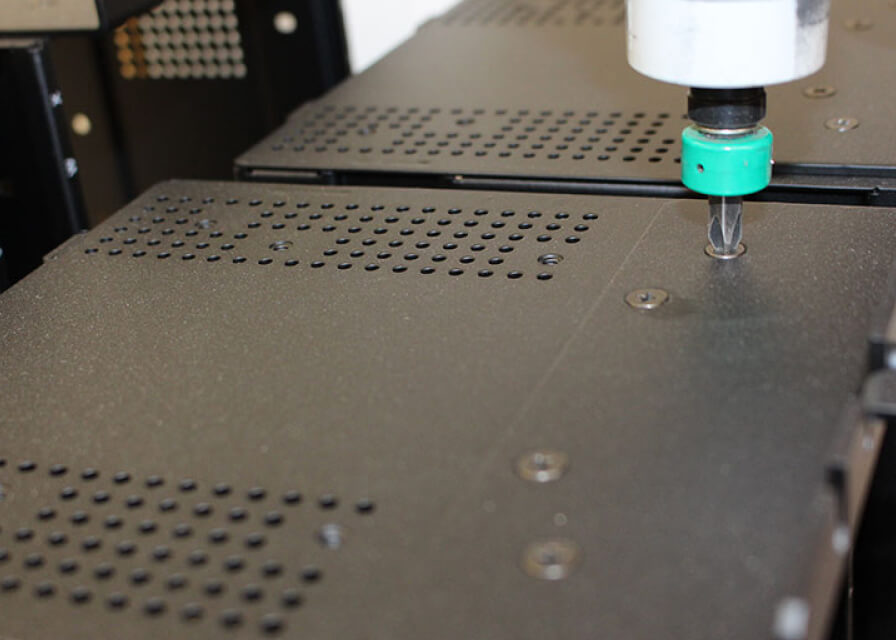

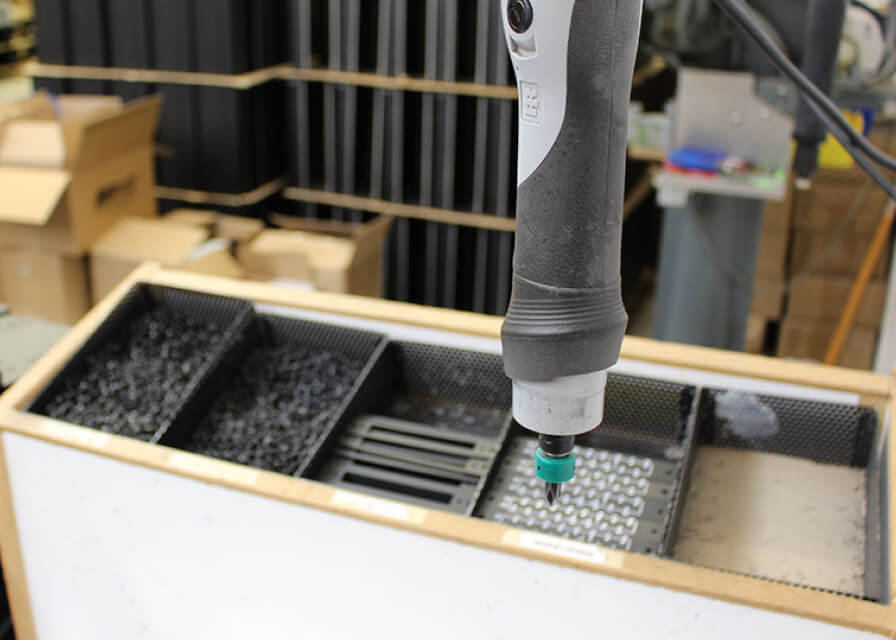

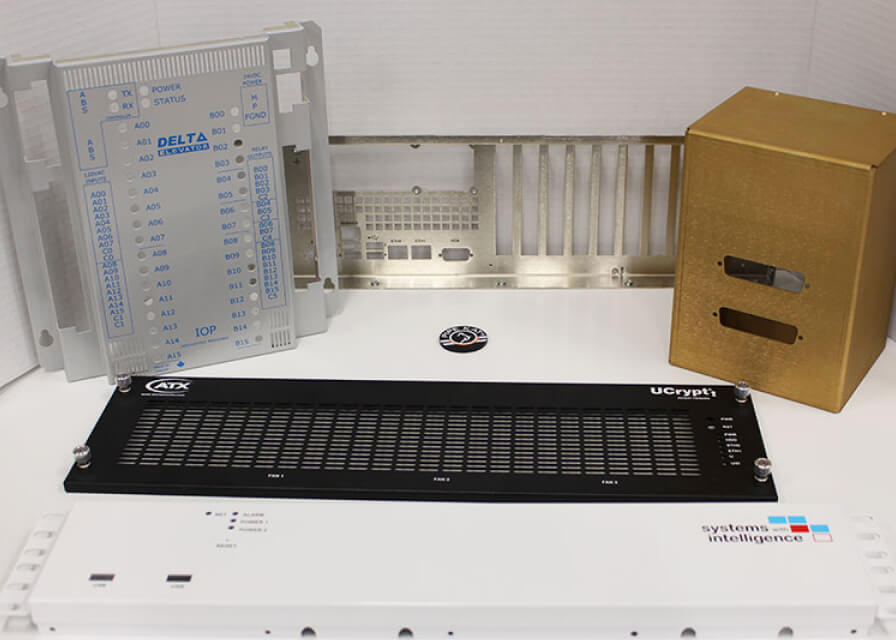

Many projects need some type of assembly or “kitting” after the finishing or paint has been applied. Auto Mach Experts has a separate building from our fabrication building where we complete these value-added services in a highly organized project-specific workcell system to conduct; sub-assembly of finished parts, light assembly of electronic accessories, card guides, cable management parts, grounding hardware and straps, DIN latches, where assembly parts are screwed or riveted together.

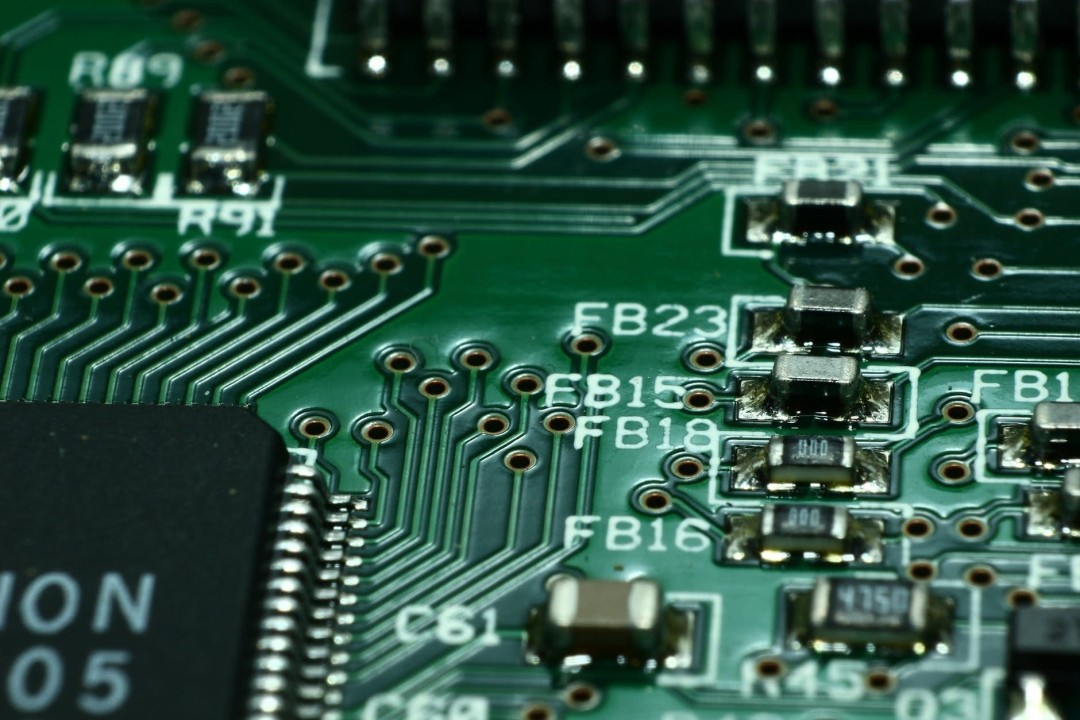

Customer-supplied products, such as small pcb’s can be installed

prior to final packaging.

Torque-calibrated automatic screw guns to ensure proper torque

when installing screws during the assembly process.

Silkscreen printing, PAD Printing, and Direct to Part Digital printing is also done at this facility.

Products are Packaged, Protected & Ready for Shipment

ith continuous Improvement, and customer satisfaction our main goals we have a commitment to meet our customers’ demands on time. Auto Mach Experts has earned a solid reputation in the industry, and as a result of this, have maintained many of the same customers over this course of time.

We take responsibility for the design and manufacture of individual tools, process development, preventive maintenance, secondary finishing or assembly processes, packaging, and final delivery to your manufacturing center.

At Auto Mach Experts Metals our dedicated and competent staff is here to ensure that all of your questions regarding the increase of productivity and gaining further market share are answered.

- Quality Protection & Packaging for shipping

- Product Specific Custom Packaging applied

- Local Deliveries using Auto Mach Exports Delivery Trucks

- Current arrangements for customer shipping worldwide, handling all customs arrangements

Final assembled products can ship directly from this facility using one of our local delivery trucks or any other shipping arrangements, as we currently ship parts worldwide for our customers.