Turret punching is the start of the process for many custom metal part projects

The primary method of cutting out sheet metal parts at Auto Mach Experts, is using a turret punch press machine. It is a highly accurate, cost effective solution to cutting out sheet metal parts using a variety of standard or custom shaped tools.

There are also many forming capabilities that can be done during this part of the manufacturing process.

Technical Point: Stand alone laser cutting machines can’t do any forming operations such as; countersinking, tapping, emboss, lance, imprinting, louvers, ribs, extruded formed holes, just to mention a few.

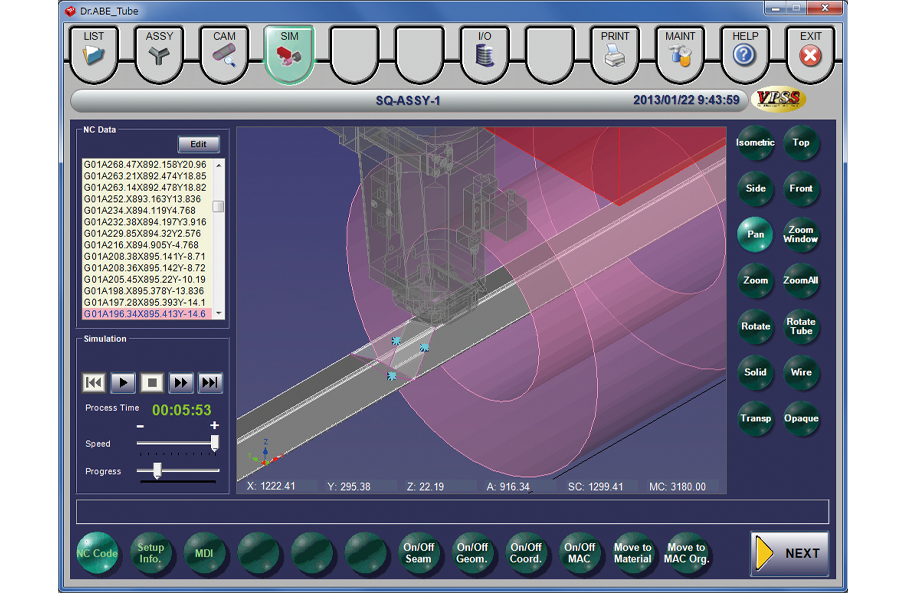

Our proven design to manufacture solution

- The process begins at the CAD/CAM design stage. Using up to date seats of Solidworks 3D CAD software, or RADAN CAM and Nesting software for imported customer designs, or parts that are designed in house.

- The designs are then flattened and processed in RADAN to machine the patterns in the most productive way, and automatically nest them into sheets to maximize sheet utilization and reduce scrap.

- Generated programs are downloaded to our Amada Turret Punch Presses for punching and forming operations.

Generated programs are downloaded to our Amada Turret Punch Presses for punching and forming operations.

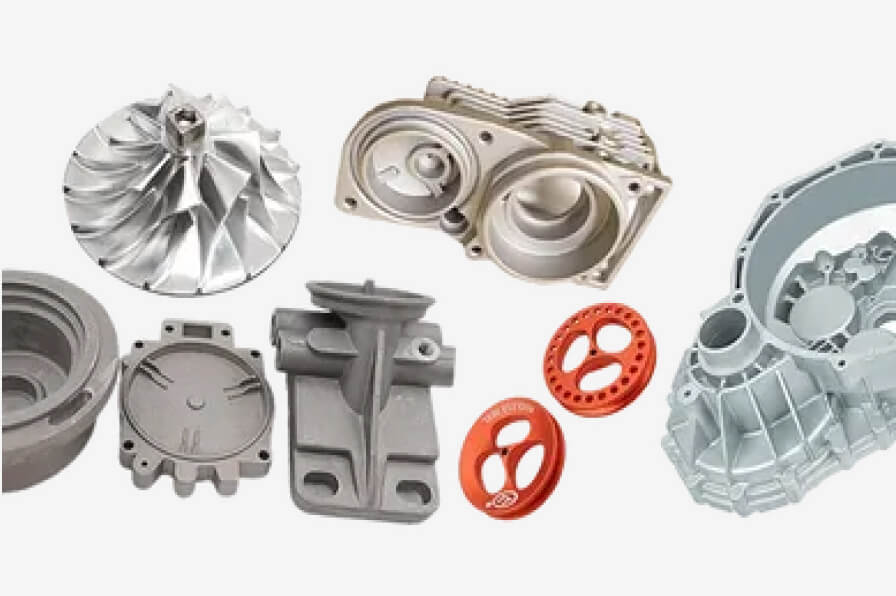

Large Selection of Special Tools

Over the years we have built an extensive library of tools that support a speedy manufacturing process with quality. These tools create;

- Louvres

- Imprint Tools

- Common shapes used for electronic and telecommunication enclosures. (RJ45, USB, Fiber ports, AC Power, etc…)

- Knockouts

- Lances

- Emboss

- Countersinks

- Extruded Holes for tapping

- Taps

Highlights of our fabrication process

Auto Mach Experts is an ISO 9001:2015 certified company that manufactures a wide variety of products to very tight tolerances such as; PCB board shrouds, housings, cabinets, control panels, chassis, bracket, panel, faceplate, heat sink, frame, card cage enclosure, or any other metal part.

- Design to Manufacturing Solutions

- 3 Amada Turret Punch Presses – Automated punching with sheet loader/unloader accepts sheet sizes up to 4×8 feet.

- Automated tapping

- Automated countersinking

- Abilities to run lights out decrease lead times, and reduces costs

Our automated amada punch press

Auto Mach Experts chooses to use Amada CNC Turret punch press machines because they have a reputation as “the best in the industry” in terms of speed, accuracy, and reliability. We have installed customized automation on the machinery so that it loads and unloads sheet stock into the machine and off loads punched out parts onto a pallet. This gives us the ability to run lights out, as well as run higher volume production runs efficiently. CNC Turret punching machines that are lights out to the competition.