Meeting customer demands

With continuous Improvement, and customer satisfaction our main goals we have a commitment to meet our customers’ demands on time. Auto Mach Experts has earned a solid reputation in the industry, and as a result of this, have maintained many of the same customers over this course of time

We take responsibility for the design and manufacture of individual tools, process development, preventive maintenance, secondary finishing or assembly processes, packaging, and final delivery to your manufacturing center.

At Auto Mach Experts Metals our dedicated and competent staff is here to ensure that all of your questions regarding the increase of productivity and gaining further market share are answered

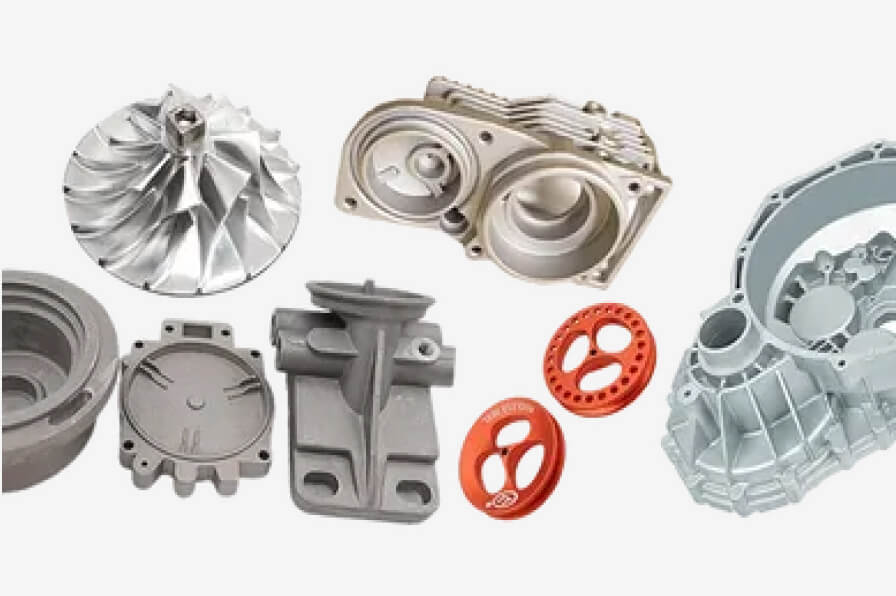

Top Quality Parts: We are very competitive with Asian markets by providing a parts inventory coupled with a JIT delivery system. Experience has demonstrated there is much less chance for product loss or damage during shipment.

Precision Machining Services

Computerized Production

- Our computerized operation begins with computer-aided design. Our Amada EMK 3510NT continues through with computerized Turret manufacturing.

- Parts move on to receive any processes not completed in the punch press such as tapping. All parts are de-burred and/or sanded depending on the application.

- From there the parts are formed up in our Press Brake department. Any specified hardware is inserted.

- Finally, our sheet metal welding line uses MIG, TIG and Spot welding for your product before any coating is applied.

FAQ’s

What types of materials do you use for custom sheet metal fabrication?

We use a variety of high-quality materials, including galvanized steel, stainless steel, and aluminum, depending on your specific needs and project requirements.

How long does the custom fabrication process take?

The timeline for custom sheet metal fabrication varies based on the complexity and scope of the project. We work efficiently to ensure timely delivery without compromising on quality.

Can you fabricate sheet metal components for existing HVAC systems?

Yes, we can design and fabricate custom sheet metal components to integrate seamlessly with your existing HVAC system, ensuring optimal performance and fit.

What Quality Certifications do you hold?

Auto Mach Experts holds ISO 9001 certification which include operators skill matrix, ECN, traceability, gauge and instruments audit.