Multiple Methods for Part Assembly

Many sheet metal parts are components of an assembly. At Auto Mach Experts, we have the capability to complete your assembly in any way required. Some of these assembly requirements may include;

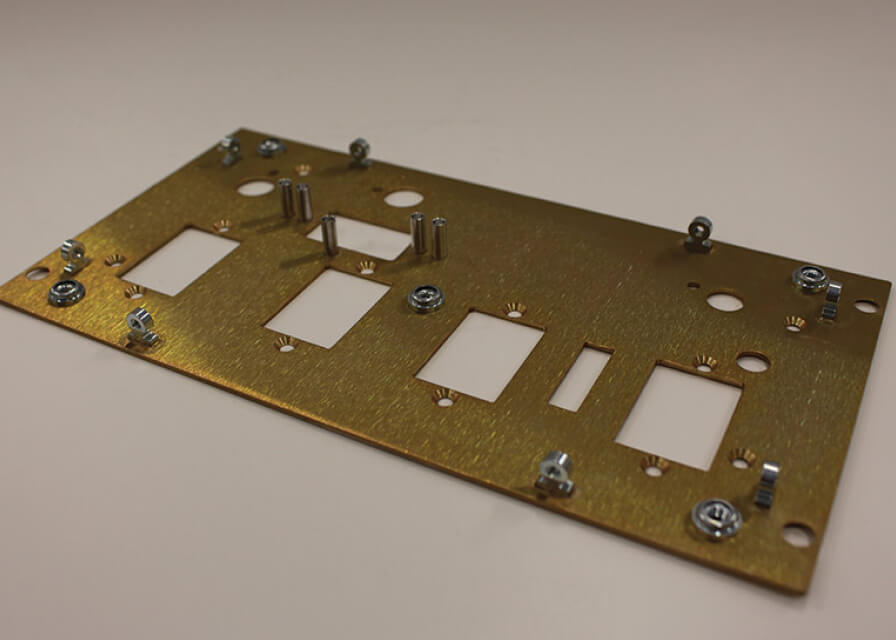

- PEM self-clinching hardware

- Weld nuts

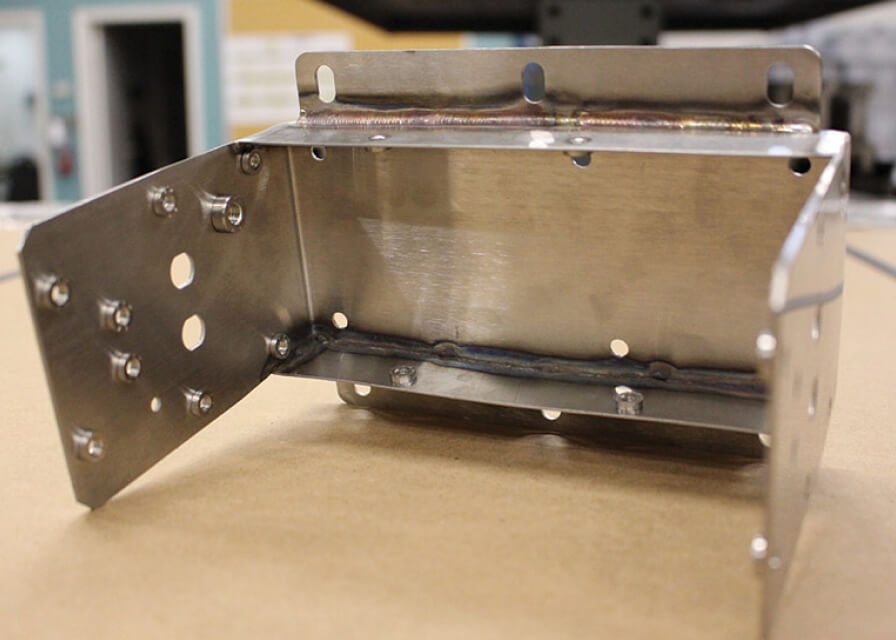

- Weldment assemblies

- Spot welded assemblies

- Rivets

- Components screwed together or other fastening methods

Below is a List of Capabilities & Machinery Used to Complete These Procedures

- Self-clinch PEM Hardware, Captive Fasteners, Thumbscrews, Weld studs, Weld nuts, Rivets

- 2 Avdel Briv strip rivet guns

- PEMserter Press machinery – 3 stations

- 10 Screw guns, calibrated to specific torque settings

- Automated presses for fast production

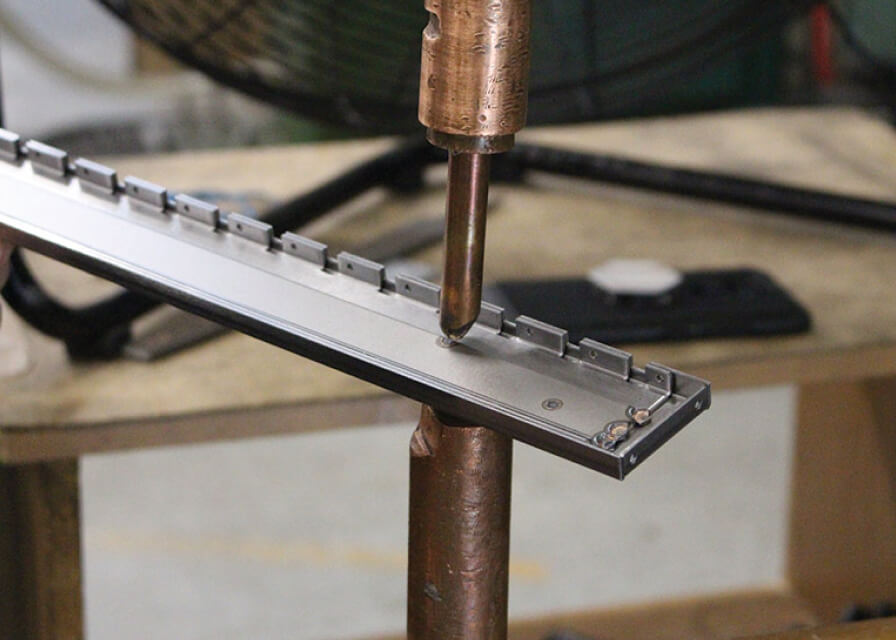

- Weld studs installed with stud welding machine

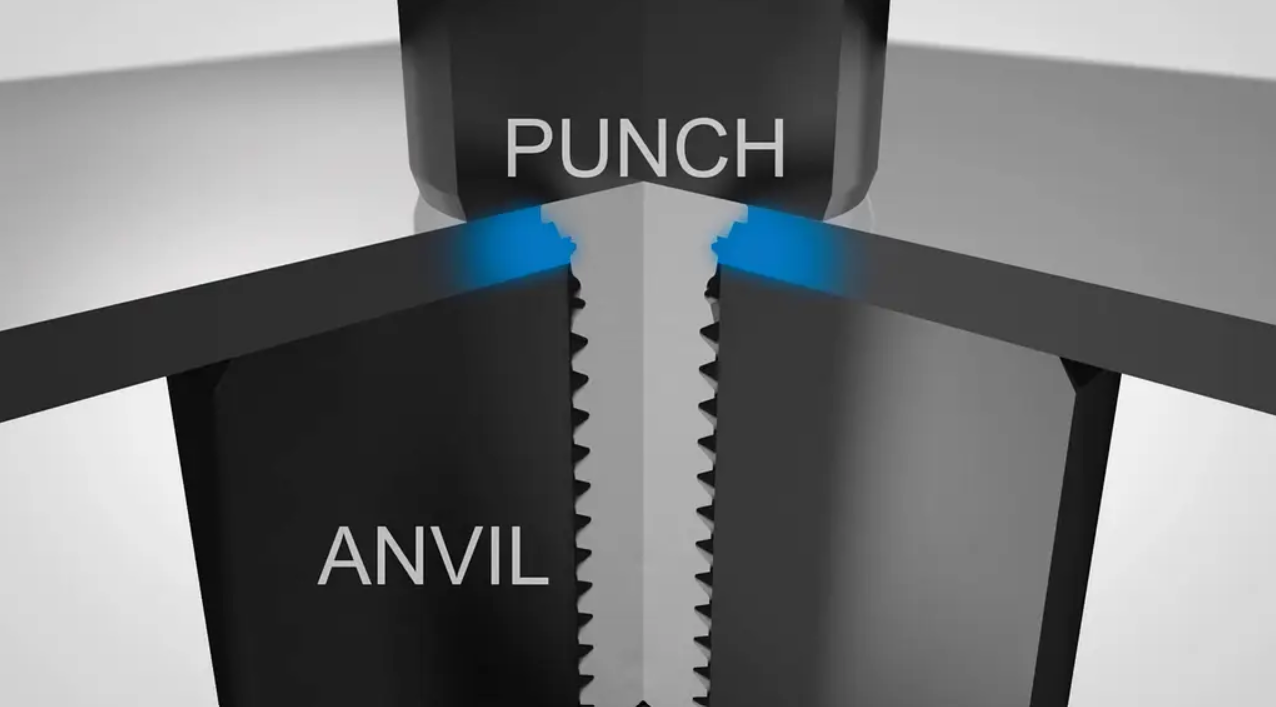

- Computer controlled for accurate tonnage pressure, ensuring clinch hardware is inserted properly.

- Weld nuts installed with spot welding machine

- Machinery is capable of pressing all styles of self-clinch hardware, Pemnuts, studs, standoffs, etc

- 2 Lithium Polymer powered Pop rivet guns

- 3 High-speed rivet machines

- 2 Spotwelding Machines

- 3 pneumatic pop rivet guns

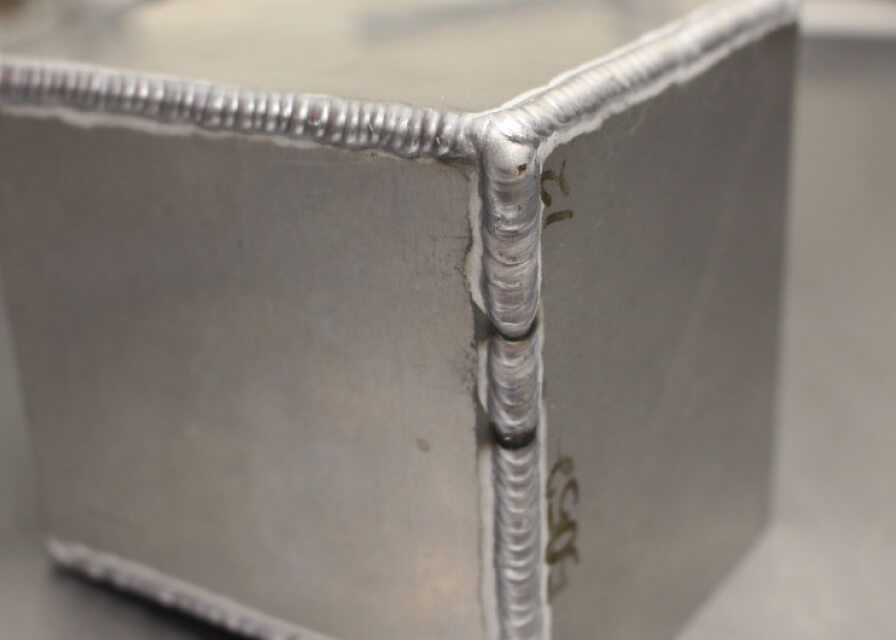

- 3 Tig Welding Stations

- 1 Mig Welding Station

Delivering Exactly What is Needed

Auto Mach Experts’ personnel follow customer design specifications to ensure a quality sheet metal assembly is built using a variety of methods.

This could range from a large weldment assembly to many parts spot welded into a sheet metal enclosure, small tack welds for strength, full seam filet welds ground smooth for assembly with a high-quality cosmetic appearance.

All PEM clinching hardware installed, complex aluminum parts

fastened with rivets,

ground studs permanently installed into the sheet metal part,

sheet metal parts fastened with screws.